EXPEC-2000 VOCs series pollution source VOCs online monitoring system is used for real-time online monitoring on the measurement of pollutants, such as methane/NMHC, characteristic factors, particulate concentration, flue gas temperature, pressure, flow rate, and statistic on the flue gas emission rate and total emissions, so that to manage the measured data effectively. The system has functions of real-time data transmission, remote fault diagnosis, data statistic, and analysis, etc., with the features of flexible configuration and low operation cost.

The measuring components of this system include methane/NMHC, benzene series, characteristic factors (such as methanol, ethyl acetate, acetone, isobutanol), and other VOCs components and particle concentration,flue gas temperature, pressure, flow rate, and other conventional parameters.

Measuring Methods Comply with the Standard

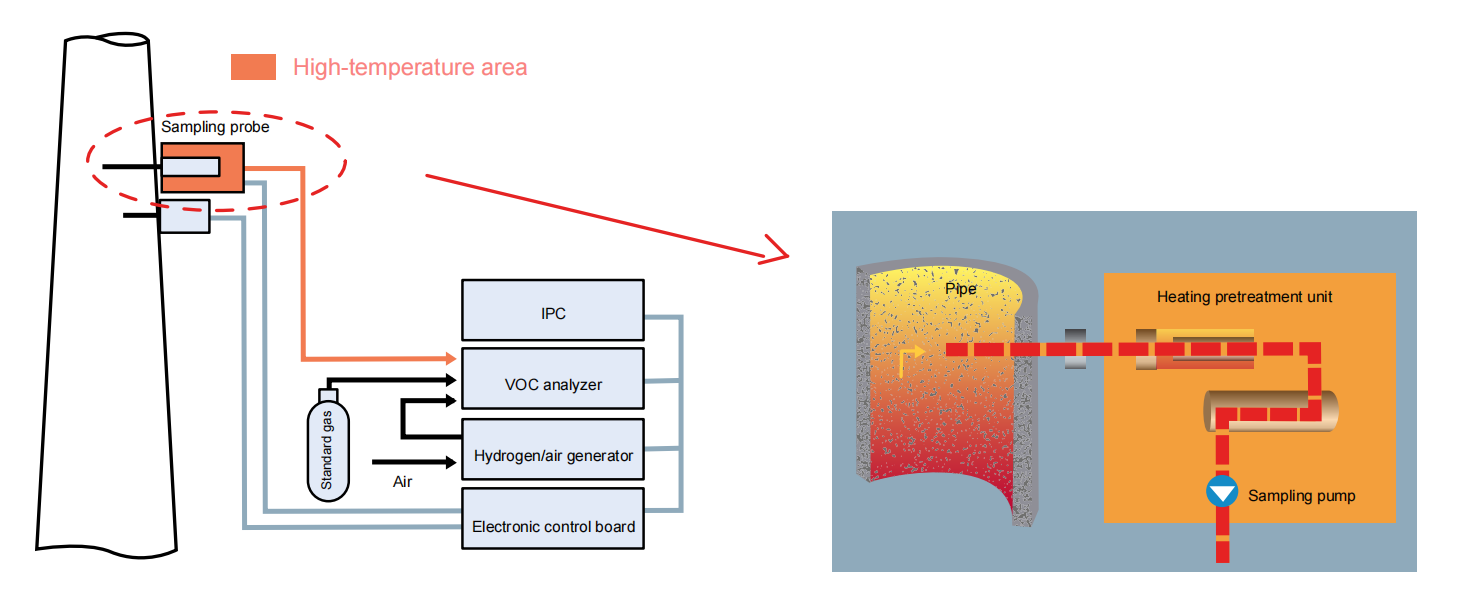

Real Complete Heat and Wet Extraction Method Design

The complete pre-injection treatment device with a self-cleaning function can effectively treat impurities such as particles and water vapor in the sample to avoid damaging the analysis system.

The sampling pipe made of PTFE or inert metal weak adsorption material can reduce the sample loss caused by adsorption of the sampling pipeline.

The system adopts the customized pre-treatment device and process control and uses a set of analyzers to alternately test samples before and after treatment.

The system adopts the complete heat and wet extraction method, avoids the adhesion of high boiling VOCs from sampling to the analysis process, and prevents corrosion degradation of components. It applies to harsh working conditions such as high boiling point, high concentration, high temperature, and corrosion.

Adapting to Multiple Applications

Ease of Operation